Lösungen für den nachhaltigen

Umgang mit Ressourcen

Die Envidatec Group vereint das Know-How aus über 20 Jahren Erfahrung und bietet Ihnen von Consulting über Engineering, Finanzierung und Betrieb das Komplettpaket für die Umsetzung nachhaltiger Energieprojekte – und das weltweit.

Neue OECD-Studie zu Klimaneutralität in Hamburg bis 2024: Zu Gast beim Klima-Forum der Handelskammer Hamburg

🌎 Klimaneutralität in Hamburg bis 2040 ist möglich: Jedes einzelne Unternehmen in Hamburg kann zum Klimaschutz beitragen. Und ganz nebenbei seine Energiekosten senken und kräftig sparen. #HandelnFürsKlima: Auch wir waren letzte Woche unter den über 800 Gästen beim Internationalen #KlimaForum in Hamburg. Die Veranstaltung war wohl eine der wichtigsten des Jahres, um den Weg zu […]

Rückblick: Energy Talk mit Sun and Charge beim Deutschen Wetterdienst

25. Januar 2024 ☀️ Vielen Dank an alle Gäste und Expert:innen, die unseren Envidatec Energy Talk am 17. Januar bereichert haben. Ein besonderes Dankeschön an die Kolleginnen und Kollegen vom Deutschen Wetterdienst (DWD) für die Gastfreundschaft, den spannenden Einblick in die Arbeit und den tollen Ausblick über die Elbe vom Dach. Man konnte sogar die […]

1,0 Bachelorarbeit: Entwicklung eines Tools zur Erfassung und Auslegung von Photovoltaiksystemlösungen

18. Januar 2024 😊 Wir gratulieren Sehid Balur ganz herzlich zu seiner 1,0 für seine Bachelorarbeit ‚Entwicklung eines Tools zur Erfassung und Auslegung von Photovoltaiksystemlösungen‘! Das von ihm kreierte Tool funktioniert nicht nur theoretisch, sondern ermöglicht auch praktisch eine schnelle Beurteilung, für wen sich eine Solaranlage rentieren könnte. Unser besonderer Dank geht an Prof. Dr. […]

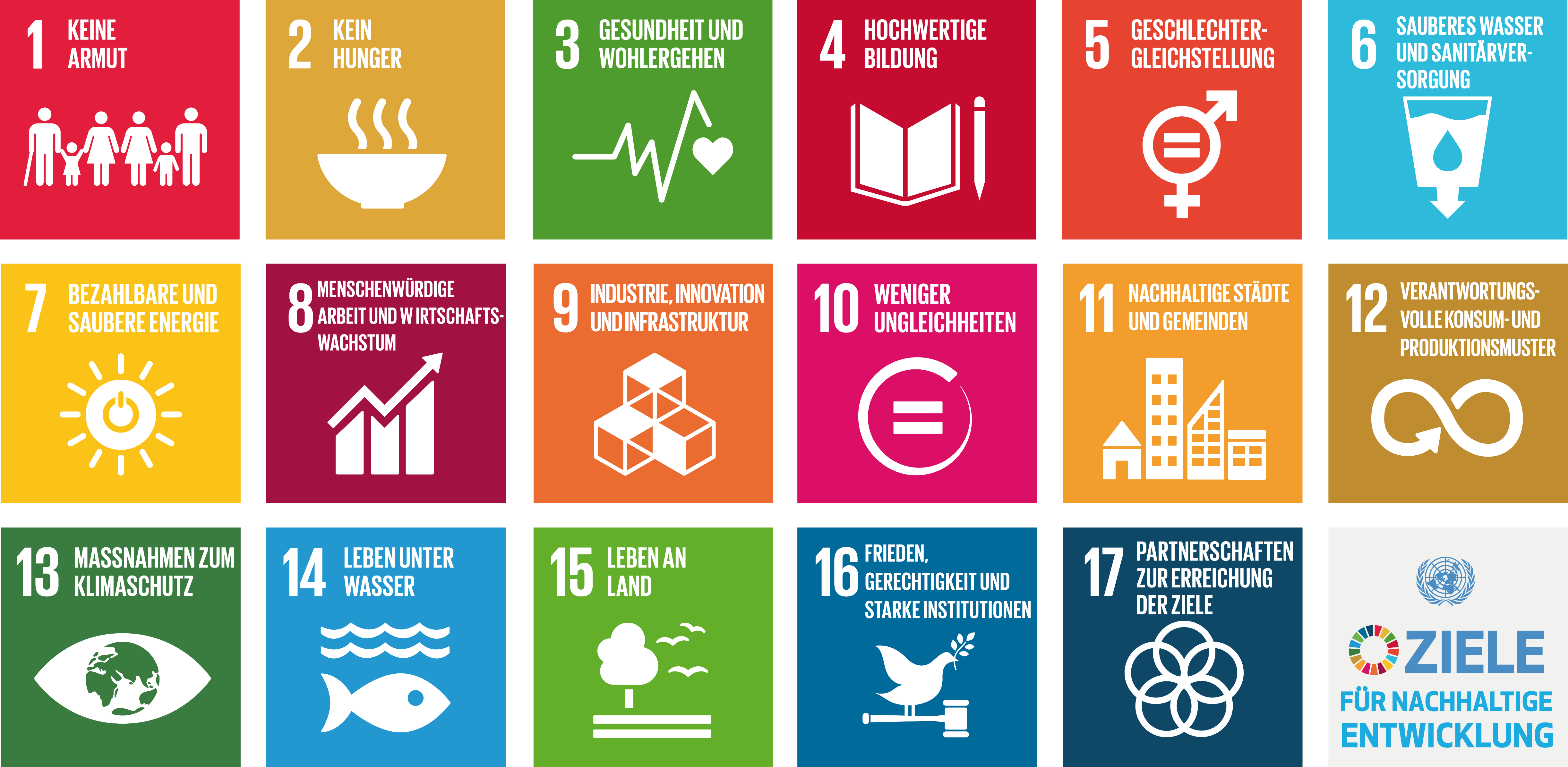

Im Einklang mit den UN-Zielen der Nachhaltigkeit

Envidatec GmbH

Seit 2001 ist die Envidatec GmbH Ihre Expertin für alle Fragen rund um Energieeffizienz: Energieaudits nach DIN EN 16247, Energiemanagementsysteme nach ISO 50001, Energiekonzepte, Erneuerbare Energien, technische Systemlösungen sowie Softwarelösungen und Beratung zur energetischen Analyse und Steuerung von Organisationen und Prozessen.

Envidatec South East Asia PTE. LTD.

Envidatec South East Asia wurde in Singapur gegründet, um dem steigenden Finanzierungsbedarf für nachhaltige Projekte in geeignetem Rechtsraum begegnen zu können. Realisiert werden innovative Finanzierungstools im Bereich FinTec. Aktuell sind Produktentwicklungen für digitale Assets in der Umsetzung, die für Crowdfinanzierungen geeignet sind.

JEVis

Software, Service & Beratung aus einer Hand: Das JEVis-System bietet – konform der ISO 50001 – Systemlösungen zur energetischen Analyse und Steuerung von Organisationen & Prozessen. Dank Open Source ist das JEVis-System äußerst flexibel, so dass auch individuelle Anforderungen effizient und herstellerunabhängig erfüllt werden können.

enPower.life Germany GmbH

enPower.life Germany GmbH ist ein unabhängiges Energieversorgungsunternehmen mit Sitz in Hamburg. Gegründet 2020, ist das Unternehmen vor allem in Schwellenländern aktiv, betreibt eigene Solaranlagen und verkauft Solarstrom. Das Geschäftsmodell schließt zudem eine Lücke in internationalen Projekten: Die Finanzierung von Solaranlagen.

Kontakt

Envidatec GmbH

Veritaskai 2 D-21079 Hamburg Deutschland

Telefon: +49 (0) 40 / 30 08 57 - 0

Telefax: +49 (0) 40 / 30 08 57 - 70

info@envidatec.com

Envidatec South East Asia PTE. LTD.

9 Battery Road

#15-01

Straits Traiding Building

Singapore (049910)